-

Company ProfileCompany ProfileEnterprise honorDevelopment coursePartners

-

Process TechnologySemiconductor Wafer Fabrication ProcessCleaning Process in FABWet EtchingPhotoresist Stripping and Cleaning

-

Single Wafer Backside EtcherBench CleaningSingle PR RemoveSingle Wafer Etcher

Photoresist Stripping and Cleaning

|

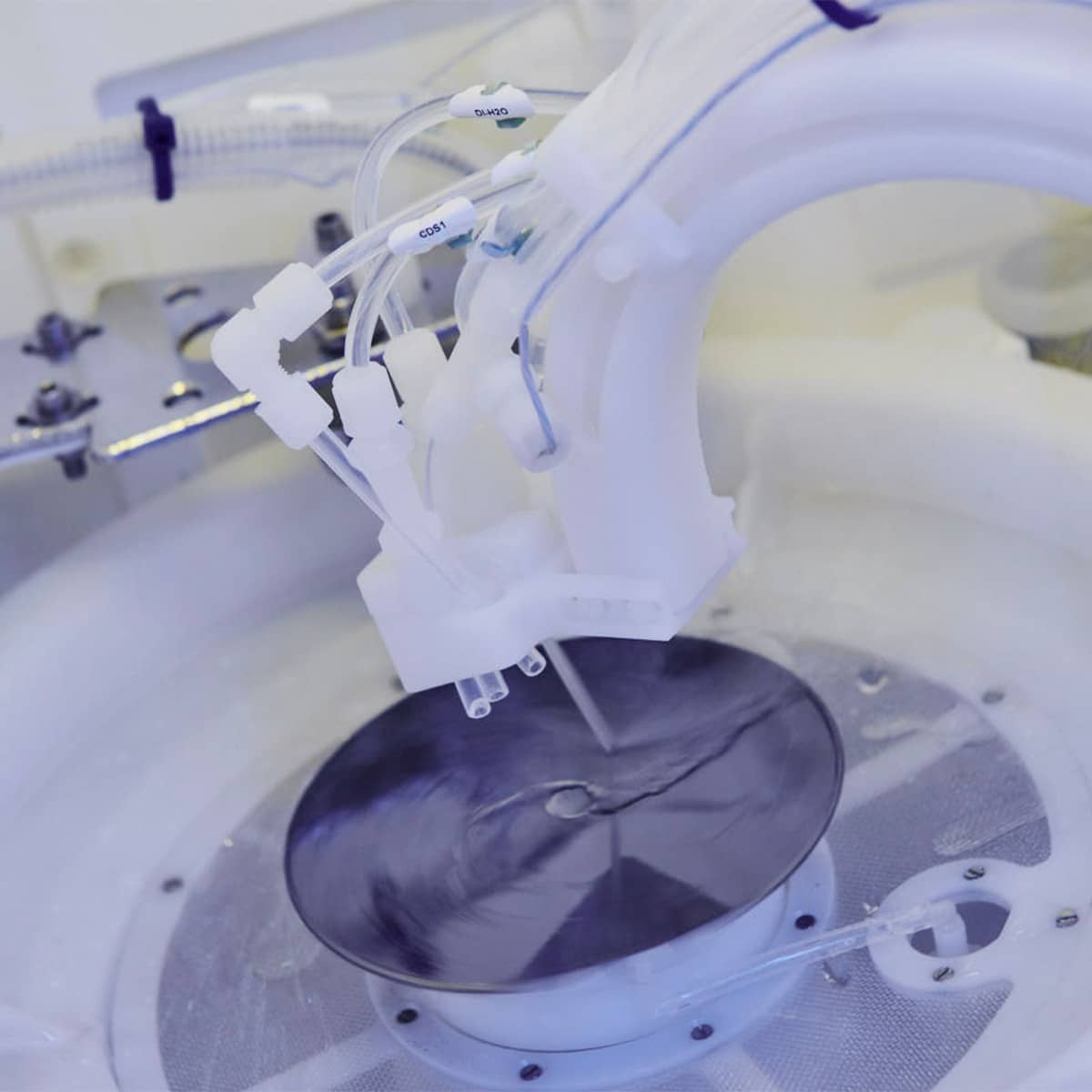

In the chip manufacturing process, resist stripping and cleaning are essential between each step to remove unwanted materials that may cause defects later, preparing the wafer surface for subsequent processing. The photoresist stripping process removes the photoresist film and residues after ion implantation or etching. Our resist stripping technology selectively removes residual photoresist, offering high process flexibility and applicability to various applications. To remove particles, contaminants, residues, and other unwanted materials, wafer cleaning steps must be incorporated throughout the manufacturing process. Cleaning is required before and after processes such as diffusion, deposition, and implantation, with each cleaning step requiring different equipment, chemical solutions, and process conditions. Semiconductor cleaning methods are diverse, including solution immersion, mechanical brushing, nano-spraying, ultrasonic cleaning, batch spray cleaning, and more.

|

Our company offers high-productivity cleaning products that ensure cleanliness from the center to the edges of the wafer. Wet processing technologies, such as wafer cleaning, resist stripping, and etching applications, can significantly improve chip yield.

Address: 101 & 201, East Unit; 102 & 202, West Unit, Building 8, Phase I, Block V, Hengtai IMP, Suzhou Nano City, No. 75 Pudian Road, Suzhou Industrial Park

Public account